John Collier Engineering asks – “Am I the last man standing?”

This account may be a trip down memory lane for some; facts for others.

Building moulding machines

In 1978, after 12 months’ training at Rochdale Technical College, I was put on the shop floor at ‘Robbies’ and assigned to No.3 department under the management of Foreman, Bill Randell. I was designated to a fitter by the name of Stevie White, who told me to forget everything I’d been taught in college as I was now officially at work.

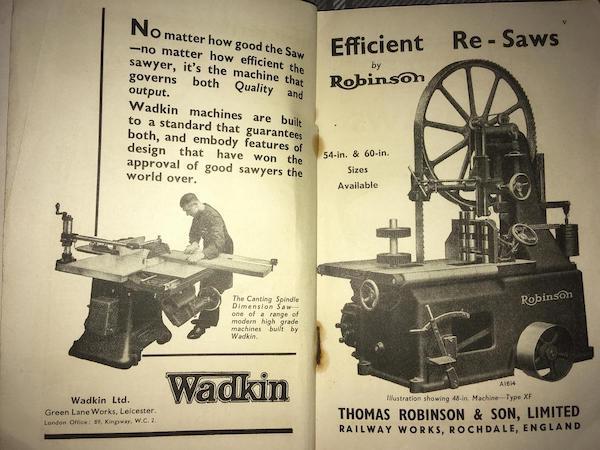

I learnt how to build moulding machines from the ground upwards – four, five and six cutters, all push feed – this was the ‘70s/‘80s. For Robinson owners and aficionados, these were types GR/T, WX/T, ZN/T and ZX/T. At the time, Jack Priestley was Works Manager. I mention this for a reason, which will become clear later.

Machine assembly

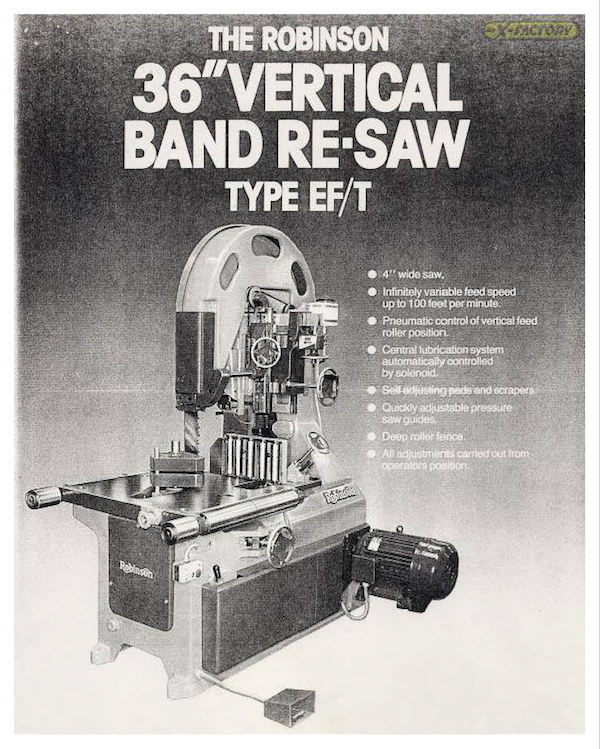

Aged 19, the piecework system we worked under made me expensive and I was cut loose along with another apprentice by the name of John Billington. Although not out of our ‘time’, John and I were charged with the assembly of machines in batches of 10, again under the piecework system; these being chain and chisel mortise and tenon SL/E; planer/thicknessers EW/T; and crosscut and EF/T band resaws.

I mention the codes for the information of Robinson owners. It was called learning the hard way – not bad for a pair of apprentices. I often wonder how 19-year-olds would fare these days, or am I getting old?

Joining Calder Woodworking Machinery

For all you old Robbies lads, our fathers were Foremen John Collier and Tom Billington, Deputy Manager. It was around this time that I started my outworking career. Armed with a company car, an address and a map, off I set.

My first appointment was at Woyka Wood, Paisley, Glasgow – a six cutter ZN/T with a broken feed. In the days before Sat Nav, finding the customer was always rewarding. As this was my first job, I felt that I’d travelled the world.

After numerous other travelling jobs, I left Robbies to join Calder Woodworking Machinery. In 1982, the Calder Service Department – run by Chris Powers – saw me working extensively throughout the British Isles on all manner of woodworking kit.

Sanding technology expert

Two of the mainstay agencies were Boere sanding machinery and Guillet pre-strengthening planing machines. I worked predominantly on this kit, and went on to become one of the foremost experts in sanding technology. As such, I was invited to the Middle East – namely UAE and Iran – to instruct and service as well as in the UK.

After three or four years repairing, installing and servicing many types – Weinig included along with Wadkin machines – I was invited to oversee the Reconditioning Workshops at Calder. John Jackson was MD at the time and gave me Broadbrush, which I took full advantage of.

There’s a Woodworking News article from around 1985/86, which writes about my new machinery inspection methods, reducing onsite guarantee work by 75%, and includes a photo of myself at the time. How we age! Oh well...

Robinsons had been bought out by the Rudd Brothers, who then bought, among other companies, Wadkin. Calder was bought and became Wadkin RMS, not long after it was closed.

John Collier Engineering

I’ve worked in many disciplines since but always as a self-employed engineer. About two years ago, Neil Priestley, who I worked with at Calder, retired. Remember his father, Jack Priestley, the Works Manager at Thomas Robinsons? Jack left Robbies in the late ‘70s to set up Priestley and Son Woodworking Engineering. As Neil has now retired, he kindly invited me to take the business forward, and I was, of course, delighted to do this.

John Collier Engineering can accommodate all of your engineering requirements, from onsite repairs service installation and movement to electrical services, full workshop machining and manufacture, including fabrication and welding of all metals.

And thus is the story so far. For all your requirements, contact John Collier on 07976 122 074 , or email [email protected].

So am I the last Thomas Robinson trained engineer that’s still operational? I’d love to know...

- Log in or register to post comments