Hoffmann’s Beaded Face Frame System – the perfect solution for cabinetmakers

The kitchen is the heart of the home, and the task of producing a high quality, tasteful kitchen falls upon the cabinetmaker. A cabinet with a beaded face frame immediately conveys a high level of quality and craftsmanship. The delicate lines and carefully rounded edge add subtle elegance and style, while precisely machined joints and accurately fitted inset doors and drawers elevate even the simplest single door design, distinctly setting it apart from utilitarian overlay-door cabinets. The most common way to manufacture beaded face frames is to use square profiles and to apply the bead profile separately.

The major disadvantage of this system is the time required to produce a complete frame. Every individual component needs to be cut, planed, squared or rounded, then mitred, glued, pinned, filled and sanded. Apart from time consumption, due to inconsistent bead profiles, mismatched grain and mitre joints can be among other the concerns. Any of these faults are also only highlighted when it comes to painting. A dissatisfied customer or a call-out will not only damage the cabinetmaker’s reputation, but also the bottom line. Clearly, the most efficient way to produce beaded face frames is to start with pre-beaded profiles – all of the disadvantages mentioned above can then be eliminated from the outset. Several systems have been devised to produce beaded face frames using pre-beaded profiles, but their set-up and calibration is a lengthy process and the high cost – over €18K plus tooling – places them out of reach of most bespoke cabinetmakers.

Beaded Face Frame Machines

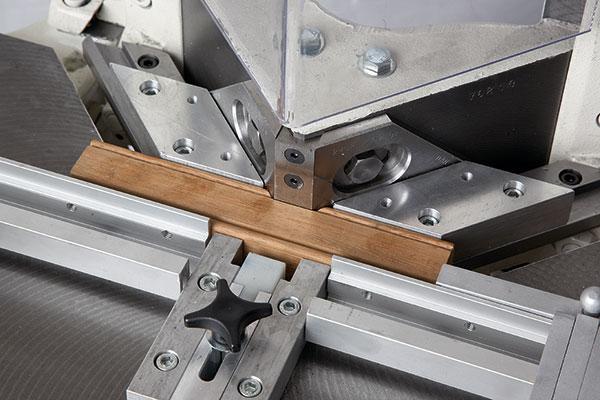

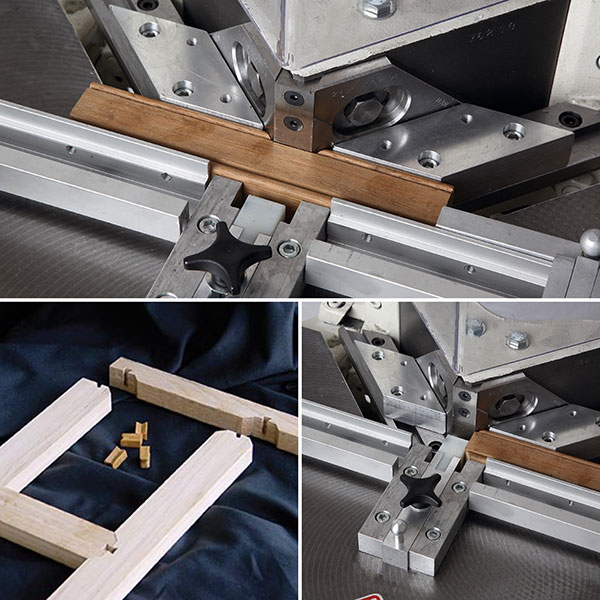

The Hoffmann Beaded Face Frame System offers cabinetmakers, of all sizes, a fast, precise and efficient method of manufacturing beaded face frames, whether in single or series production. Starting with pre-beaded profiles, stiles are notched in pairs and the rails coped on a fixed blade Morso guillotine-style notching machine. These NF series machines are manufactured for Hoffmann by Dan-List (Morso) in Denmark. They cut all kinds of wood, plastic, MDF and plywood, and leave the cut surface of the profile perfectly smooth and accurate, requiring no further preparation before joining. For a standard stile-to-rail connection, this operation takes about five seconds using Hoffmann’s manual foot-operated notching machine, and the automatic model is even faster.

The second step takes place on the Hoffmann MU-3 dovetail routing machine, equipped with special fixtures for beaded and notched material. Dovetail keyways are routed into all mating parts and the frames assembled by applying glue and inserting Hoffmann Dovetail Keys. These Keys draw the parts together to form a tight, secure, permanent joint. No large clamping tables or bar clamps are required and the frames can be finished immediately upon assembly. All dovetail routing machines are supplied with a complete fixture set to process stiles and rails, but can also be used to process regular mitre and butt joints. They are also available in digital and pneumatic models, thus increasing accuracy and speed.

To find out more about these solutions offered by Hoffmann Machine Company Ltd, call 01524 841 500, email [email protected] or visit www.hoffmann-uk.com.

|

Hoffmann Machine Company Ltd

Unit 8 Borrowdale Business Park

Whitegate, White Lund

Morecambe, Lancs. LA3 3BS

01524 841 500

|

- Log in or register to post comments